By integrating industrial knowledge and technology, Pou Chen has linked the upstream, midstream and downstream businesses in the footwear industry and formed a complete supply chain. With the goal of providing customers with rapid responsive services, the Company continues improving manufacturing processes, enhancing production flexibility, and building a responsive material supply system that is sensitive to the market, so as to develop its long-term value.

Based on the vision of “resource integration and value increase”, Pou Chen has set short-, mid-, and long-term goals and expects to realize its corporate social responsibility and the sustainable development goal by developing more new materials, new processes, new technologies, and new applications, as well as developing product creativity and its added value. The short-term goal is to continue optimizing the vertically integrated supply chain management system by integrating the Group’s resources and to provide comprehensive solutions to meet customers’ needs. The mid- and long-term goal, apart from continuously enhancing the quality and the competitiveness of cost, is to expand suppliers’ R&D and sustainable development capabilities to innovate applications, upgrade manufacturing processes, and refine materials with suppliers.

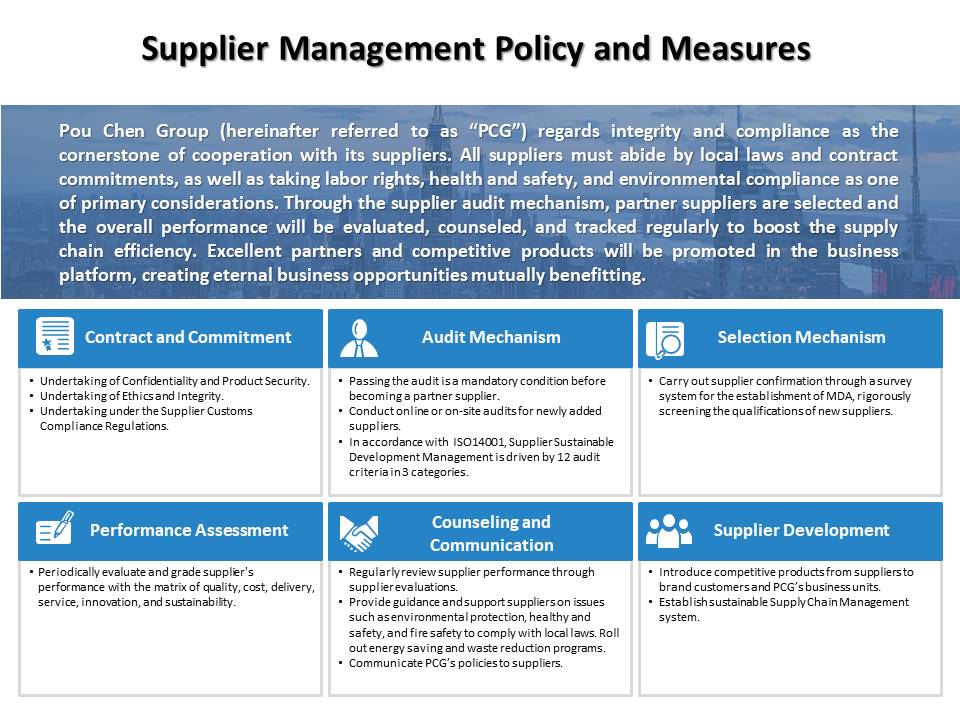

Supplier Management Policy and Measures

Supplier Review

Except as specified by customers or specific material suppliers, the Company adopts ISO 9001:2015 quality standards, ISO14001:2015 environmental standards, and the human rights standards outlined in the Group's Supplier-Friendly Workplace Guidelines. We also incorporate local environmental protection and labor rights regulations, along with other preventive measures, as management indicators in the screening of new suppliers. The proportion of new suppliers screened according to these criteria is 100%.

In terms of quality management, we utilize surveys to assess suppliers’ business status, quality management systems, supply capacity, and service and delivery capabilities. To effectively manage suppliers and ensure that purchased items meet the requirements of the Company and its brand customers, suppliers under audit must address defects and outline their improvement measures according to the PDCA (Plan, Do, Check, Act) principle. This approach strengthens suppliers’ quality management, reduces the costs associated with quality failures, and ensures that the incoming materials at each factory comply with brand standards. Additionally, suppliers are required to fully adhere to the RSL (Restricted Substances List) standards set by each partner brand.

For environmental safety, health, and human rights management, raw materials and machinery suppliers undergo an initial document review of their environmental impact assessments, pollution discharge permits, and pollution prevention measures to ensure normal operation. This includes reviewing labor contracts, compliance with wage and working hour regulations, assessing the risk of forced labor, and verifying the existence of grievance management mechanisms and other human rights considerations. Following this, assessments are conducted on the operation site to identify risks related to safety and health, environmental protection and fire safety. For suppliers specializing in project contracting, their business licenses, environmental safety and health qualifications, personnel certificates, and occupational safety and health management plans are also reviewed for legal compliance.

Supplier Management and Counseling Mechanism

In addition to maintaining the selection criteria for new suppliers, we integrate the specifications of brand customers to identify key Tier 1 suppliers for management disclosure. Our management methods include periodic written evaluations, annual reviews, and support through on-site inspections or remote video conferencing, with both notified and unannounced assessments. The review methods encompass verifying statutory documents and permits, evaluating policies on environmental safety, health, and human rights, and conducting on-site visits, dormitory inspections, and employee interviews. We encourage outstanding suppliers to promote a circular economy and recognize their highlight projects. Furthermore, we require all Tier 1 suppliers to obtain legal environmental permits and undergo regular inspections. For those not meeting the Company’s sustainability management standards, we provide guidance for improvement and may reduce procurement volume as necessary to maintain a quality supply chain management system.

Supplier Development

Pou Chen views suppliers as partners, values interaction and communication with them, and assists and coaches suppliers to strengthen quality and sustainable development management, enhancing the competitiveness of the Group's suppliers and increasing the overall value of the supply chain.

In the area of sustainable development management, we expand different levels of projects with suppliers based on our partnerships. In addition to holding supplier meetings with brand customers, we conduct training on compliance standards and promote the Supplier Friendly Workplace Guidelines, inviting suppliers to sign commitments. We have also introduced carbon management counseling projects to align suppliers with international sustainable trends. Furthermore, for key suppliers with strong partnerships, we implemented projects aimed at reducing occupational hazards and establishing complaint mechanism.